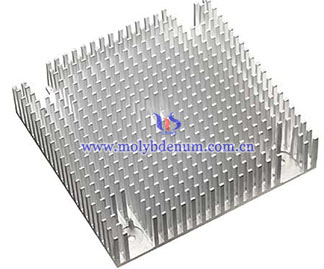

Molybdenum Copper Heat Sink

Molybdenum copper heat sink has good electricity conductivity is suitable for aeronautic and astronautic applications.

Advantages of molybdenum copper heat sink

excellent hermeticity

Relatively small density

Stampable sheets available (Mo content no more than 75 wt%)

Semi-finished or finished (Ni/Au plated) parts available

A heat sink is a term for a component or assembly that transfers heat generated within a solid material to a fluid medium, such as air or a liquid. Examples of heat sinks are the heat exchangers used in refrigeration and air conditioning systems and the radiator (also a heat exchanger) in a car. Heat sinks also help to cool electronic and optoelectronic devices, such as higher-power lasers and light emitting diodes (LEDs).

A heat sink is physically designed to increase the surface area in contact with the cooling fluid surrounding it, such as the air. Approach air velocity, choice of material, fin (or other protrusion) design and surface treatment are some of the design factors which influence the thermal resistance, i.e. thermal performance, of a heat sink. One engineering application of heat sinks is in the thermal management of electronics, often computer central processing unit (CPU) or graphics processors. For these, heat sink attachment methods and thermal interface materials also influence the eventual junction or die temperature of the processor(s). Thermal adhesive (also known as thermal grease) is added to the base of the heat sink to help its thermal performance. Theoretical, experimental and numerical methods can be used to determine a heat sink's thermal performance.(This is from Wikipedia.)

Molybdenum copper is chosen as material of heat sink having the special properties of molybdenum copper. Molybdenum copper can be produced in our company.